Share:

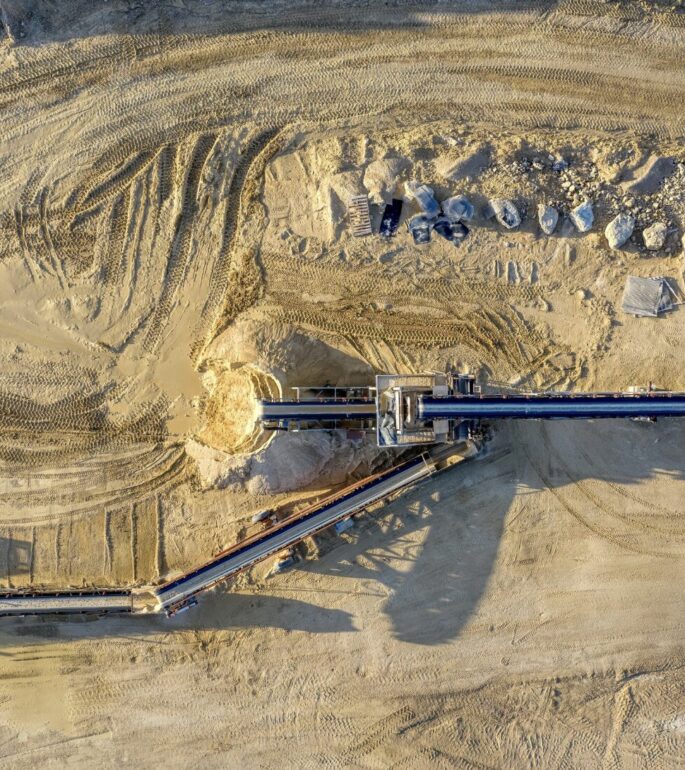

The client is a leading entity in India’s iron and steel industry, committed to addressing the environmental challenges associated with its operations. They have built a strong reputation in mining and production, particularly in iron ore mining, with significant operations in Maharashtra, including the Ghugus and Konsari steel plants and the Surjagarh iron ore mines. With growing concerns about climate change and the global push towards sustainability, they recognise the need to adopt a comprehensive decarbonisation strategy to reduce its carbon footprint and enhance its operational efficiency.

The decarbonisation strategy for the client focuses on reducing emissions across key areas of its operations, including diesel combustion, electricity consumption, fugitive emissions, and process emissions. This strategy is aligned with regulatory frameworks and leverages advanced technologies to ensure both environmental sustainability and operational efficiency.

The client’s emissions data highlighted several areas that needed attention or immediate intervention, particularly in diesel emissions, which were significantly high due to the heavy reliance on diesel-powered vehicles and machinery. Stationary combustion contributed xx tCO2e, while mobile combustion accounted for a substantial xx tCO2e. Additionally, electricity-related emissions were significant at xx tCO2e, indicating increased operational activities or higher energy demands. Fugitive emissions from refrigerants like R-134 and R-410A were also notable, with emissions of xx tCO2e and xx tCO2e, respectively, highlighting potential issues with leakage or elevated usage. Although process emissions were relatively lower, the use of Bulk Emulsion Explosives contributed significantly, indicating a need for focused improvements in this sector.

To address these challenges, the client has identified several key opportunities for emission reduction:

a) Diesel Emissions: The client plans to transition to alternative fuels such as biodiesel, hydrogen, and electric power for both stationary and mobile applications. This includes the adoption of fuel-efficient technologies and practices, regular maintenance, and upgrading to newer, more efficient models.

b) Electricity Consumption: The client is exploring the feasibility of a 20MW solar plant at the mine to reduce reliance on conventional electricity and lower associated emissions. The company aims to power all-electric vehicles (EVs) and light motor vehicles (LMVs) with solar energy by the end of 2025, significantly decreasing its dependence on non-renewable electricity sources.

c) Fugitive Emissions: The client plans to enhance leak detection practices for refrigerants, transition to low-global-warming-potential (GWP) alternatives and improve staff training on proper handling and maintenance of refrigerants to prevent accidental releases.

d) Process Emissions: The client will evaluate and optimise processes involving Bulk Emulsion Explosives to reduce emissions, implement strategies to reduce waste generation, and adopt more efficient technologies.

e) Operational Efficiency: The project identified key emission hotspots and recommended operational adjustments to enhance process efficiency. This involved upgrading the infrastructure of both the mine site and the plant to reduce emissions

These initiatives represent a significant step towards reducing the client’s overall emissions. For instance, the transition to electric vehicles (EVs) in mining operations is expected to reduce diesel emissions by up to 100% if charged with solar energy. Additionally, the planned solar plant will eliminate 100% of Scope 2 emissions, reflecting the client’s commitment to sustainability and environmental responsibility.

The client’s decarbonisation strategy is further supported by leveraging recent regulatory and policy changes. By adopting sustainable mining practices, utilising funds for sustainable development, and exploring strategic investments, the client aims to enhance its operations and reduce emissions, thereby improving overall environmental performance.

After conducting a cost-benefit analysis of the decarbonization measures, it became clear that the client was achieving significant cost savings. Additionally, with their carbon intensity well below that of their competitors, the client views this initiative as a strong opportunity to grow their business, increase sales, and enhance revenue.

Purpose and scope of this Decarbonisation Roadmap

The purpose of the Decarbonisation Roadmap is to outline the client’s strategic approach to significantly reducing its carbon emissions in alignment with global climate goals. The roadmap serves as a comprehensive guide for the client’s journey towards a low-carbon future, detailing the specific actions, timelines, and technological innovations that the company will employ to achieve its decarbonisation targets.

The scope of the roadmap encompasses all aspects of the client’s operations, including but not limited to mining, processing, manufacturing, and logistics. It covers both direct emissions (Scope 1) from the client’s industrial activities and indirect emissions (Scope 2) associated with energy consumption. The roadmap also addresses the integration of renewable energy sources, energy efficiency measures, and product improvement technologies, as well as strategies for engaging stakeholders and reporting progress transparently.

By defining clear objectives and actionable steps, this Decarbonisation Roadmap aims to position the client as a leader in sustainable industrial practices, ensuring long-term environmental responsibility and compliance with evolving regulatory standards.

The process:

The project team key objectives were to:

- Calculate the carbon emissions (Scope 1 and Scope 2)

- Create a baseline and calculate the carbon intensity reduction deriving from ongoing and upcoming initiatives

- Benchmarking with other industry peers and ensuring that their iron ore’s carbon intensity and emission levels are below industry-par

- Create comprehensive data-driven reports for stakeholders and Ministries to showcase the client’s initiatives to reduce their iron ore intensity

The project was comprehensive and required our consultants to undertake:

- Estimated carbon emission in a non-improvement scenario: If the client continues its current operations without implementing decarbonisation measures, the projected carbon emissions.

- A detailed overview of the mining sector in India, the regulations related to carbon emissions from mining with an emphasis on the regulatory changes.

- Summary of emission areas: providing emissions data insights into several key areas of concern and improvement areas.

- Identification of emission reduction opportunities: Focus areas for improvement that are prioritised based on substantial contributions to the overall carbon footprint and their potential for impact.

- A detailed review of the current planned emission reduction initiatives and how they contribute to carbon intensity reduction.

- A review of how the client can leverage the recent regulatory and policy changes to enhance its operations and reduce emissions.

- A detailed review of the impact of the current emissions reduction activities on overall emissions.

- Cost-benefit analysis

- A detailed analysis of the client’s confidential scenarios, calculating baseline and projected emission reductions

The comparison between the current and proposed scenarios highlighted the client’s potential for significant decarbonisation by adopting the recommended (confidential) initiatives. The overall emission intensity is reduced from xx tCO2e per ton to xx tCO2e per ton, representing a 61.5% reduction in the carbon footprint of the client’s ore production process. This reduction is achieved through targeted interventions at each stage, such as low-emission mining practices, efficient ore beneficiation, and other interventions.

Conclusion:

The client demonstrated a strong commitment to environmental sustainability by developing a comprehensive decarbonisation strategy that addresses the significant carbon emissions associated with its operations. This strategy not only aligns with global climate goals but also positions the client as a leader in sustainable practices within the iron and steel industry.

The comprehensive Decarbonisation Roadmap conducted by the team analysed all the currently available data and used this to compare scenarios to validate the client’s decarbonisation strategy against their ongoing and upcoming initiatives.

The client’s decarbonisation strategy is a testament to the company’s dedication to making a positive impact on the environment. As the company continues to implement these initiatives, it will play a crucial role in driving the transition towards a low-carbon economy and setting a benchmark for sustainability in the industry.

Disclosure:

Certain sensitive and confidential information has been omitted to safeguard the client’s interests and could be disclosed in their annual report.

If you'd like to learn more about how a decarbonisation roadmap will benefit your business

Popular Reads

A guide to CDP reporting for 2025